Today, we are going to demystify the difference between two essential tools in the world of welding: the welding torch and the welding gun. While their names may sound similar, these tools serve distinct purposes and have unique features that cater to specific welding techniques. Join us as we explore the characteristics that set these tools apart, providing you with a deeper understanding of their functions and helping you make informed decisions when it comes to selecting the right equipment for your welding projects.

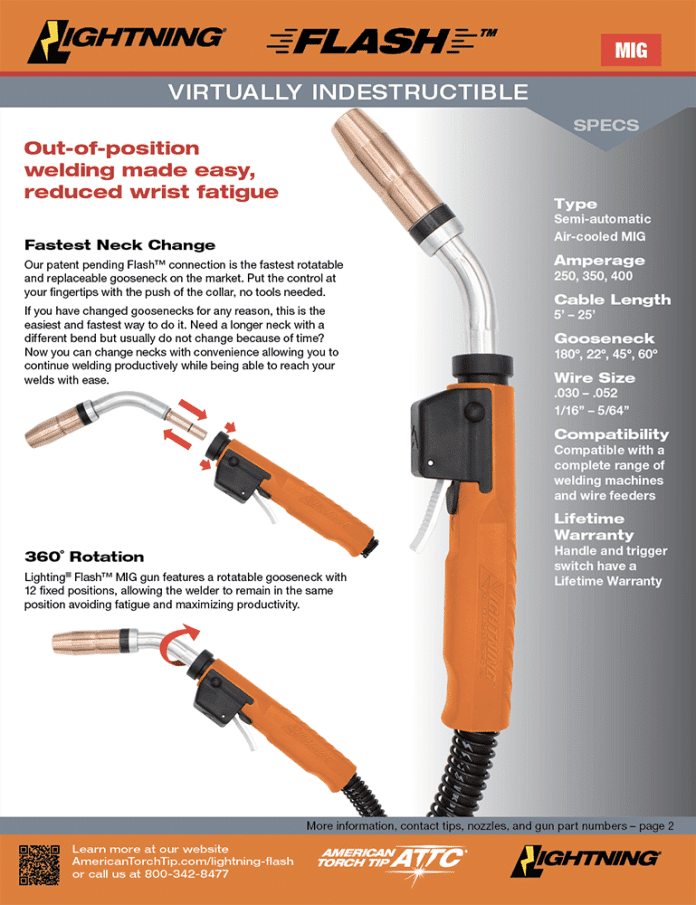

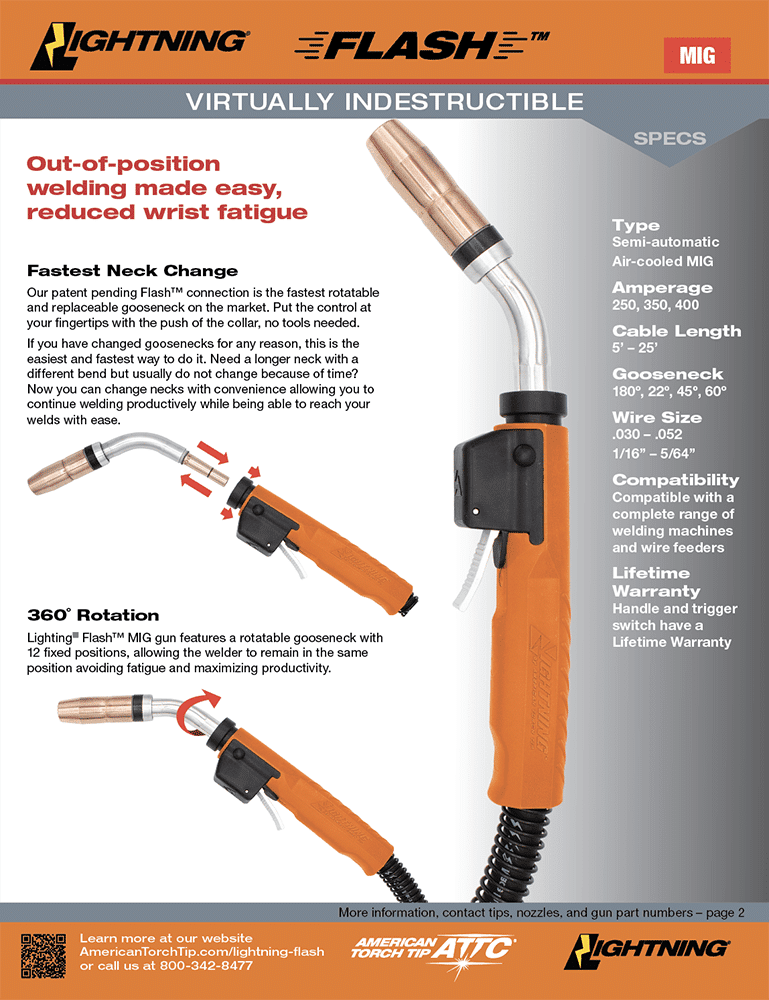

This image is property of americantorchtip.com.

Review contents

Definition of Welding Torch

What is a welding torch?

A welding torch is a tool used in the field of welding to produce flames or heat by burning gases. The torch is designed to create a localized heat source to melt materials, such as metal, so that they can be joined together or manipulated for various purposes.

Functions of a welding torch

The primary function of a welding torch is to supply the necessary fuel and heat required for welding operations. It allows the welder to control the intensity and direction of the flame, making it an essential tool for precision and accuracy in welding. Additionally, a welding torch can be used for cutting metal, heating metal to achieve specific temperatures, and brazing metal.

Components of a Welding Torch

Gas cylinder

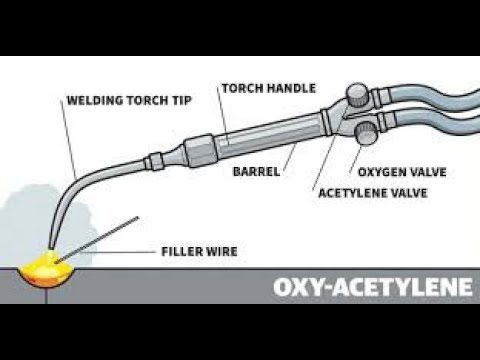

The gas cylinder is the container that holds the fuel gas, such as acetylene or propane, which is used for the welding process. It is typically constructed from durable materials and is equipped with valves for controlling the flow of gas.

Regulator

The regulator is a device that is attached to the gas cylinder. Its main function is to control the flow and pressure of the gases. It ensures that the welding torch receives the appropriate amount of fuel gas, allowing for precise and efficient welding operations.

Hose

The hose connects the gas cylinder to the welding torch. It is designed to withstand the high pressure of the gas and deliver a consistent flow from the cylinder to the torch. The length of the hose varies depending on the specific welding task and the desired mobility of the welder.

Handle

The handle of a welding torch is the part that the welder holds onto during operation. It is typically ergonomically designed to provide comfort and control while using the torch. The handle may contain various controls, such as a trigger or valve, allowing the welder to regulate the flame intensity and gas flow.

Mixing chamber

The mixing chamber is a critical component of a welding torch where the fuel gas and oxygen or air are combined. It ensures the proper mix of gases before they are ignited, providing a stable and controlled flame for welding operations.

Nozzle

The nozzle is the tip of the welding torch where the flame is emitted. It is responsible for shaping the flame and directing it onto the workpiece. The size and shape of the nozzle can be changed to accommodate different welding techniques and applications.

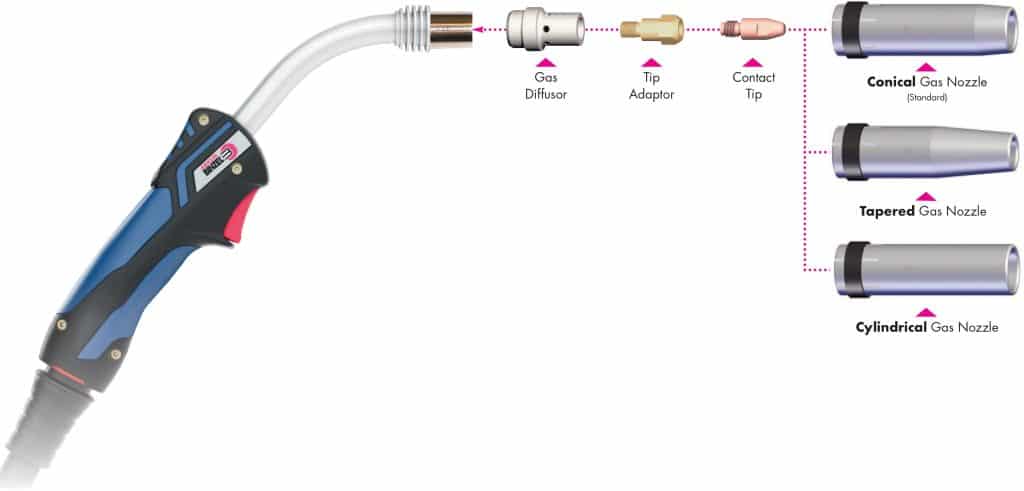

This image is property of blog.binzel-abicor.com.

Types of Welding Torches

Oxy-Acetylene Welding Torch

An oxy-acetylene welding torch is a type of welding torch that uses a combination of acetylene gas and oxygen to produce a high-temperature flame for welding and cutting operations. This type of torch is commonly used in metal fabrication, repair work, and artistic applications due to its versatility and precision.

Oxy-Propane Welding Torch

An oxy-propane welding torch, as the name suggests, utilizes propane gas instead of acetylene to generate the flame. Propane is often chosen as an alternative fuel due to its lower cost and availability. Oxy-propane torches are commonly used in applications where the high temperature produced by acetylene is not necessary.

Uses of Welding Torches

Cutting metal

One of the primary uses of a welding torch is cutting metal. By combining the fuel gas and oxygen in the appropriate proportions and directing the flame onto the workpiece, the torch can generate a localized high-temperature area that melts through the metal, allowing for precise and controlled cutting.

Joining metal

Welding torches are primarily used for joining metal pieces together. By melting the materials at the joint using heat from the torch flame, the molten metal can fuse, creating a strong and permanent bond between the two pieces.

Heating metal

A welding torch can also be used to heat metal to specific temperatures. This can be useful in processes such as preheating before welding to improve the weld quality or annealing to relieve internal stresses in the material.

Brazing metal

Brazing is a process that involves joining metal pieces together using a filler metal that flows between the joints. A welding torch can provide the heat necessary to melt the filler metal, allowing it to bond the parts. This technique is commonly used for joining dissimilar metals or when a higher strength joint is required.

This image is property of i.ytimg.com.

Definition of Welding Gun

What is a welding gun?

A welding gun is a handheld tool used in welding processes that delivers a controlled electric current to create an arc between the electrode and the workpiece. The arc generates the heat required to melt the metal, which can then be joined together.

Functions of a welding gun

The primary function of a welding gun is to provide a controlled means of delivering the electric current to the welding arc. It allows the welder to manipulate the position and movement of the electrode, ensuring precise control over the welding process. Additionally, a welding gun may have additional features, such as a gas nozzle, to supply shielding gas or flux during specific welding techniques.

Components of a Welding Gun

Electrode holder

The electrode holder is a part of the welding gun that holds the welding electrode securely in place. It allows for easy installation and replacement of the electrode, ensuring a consistent and reliable electrical connection.

Contact tip

The contact tip is a consumable part of the welding gun that comes into direct contact with the workpiece. It acts as the point of contact for the electric current and guides the electrode’s position during the welding process. The contact tip should be regularly inspected and replaced if it becomes worn or damaged.

Trigger

The trigger is a control mechanism on the welding gun that allows the welder to initiate and stop the flow of current. By pressing the trigger, the circuit is completed, and the welding arc is generated. Releasing the trigger interrupts the current flow, preventing further welding.

Gas nozzle

Some welding guns are equipped with a gas nozzle, also known as a gas diffuser or gas cup. It is used in processes such as MIG (Metal Inert Gas) welding or TIG (Tungsten Inert Gas) welding to supply a shielding gas to protect the weld pool from oxidation or contamination.

Power cable

The power cable is responsible for delivering the electric current from the welding machine to the welding gun. It is designed to withstand the high electrical load and is often insulated to ensure safe operation. The length of the power cable may vary to accommodate different welding setups and working environments.

This image is property of do-it-up.com.

Types of Welding Guns

MIG Welding Gun

A MIG welding gun, or MIG torch, is specifically designed for MIG welding processes. It utilizes a consumable electrode wire, which is continuously fed through the gun and creates an arc with the workpiece. MIG welding guns are popular due to their ease of use and high deposition rates.

TIG Welding Gun

TIG welding guns, or TIG torches, are commonly used in TIG welding processes. They employ a non-consumable tungsten electrode to generate the arc, and a separate filler metal is added manually, if necessary. TIG welding guns are known for their ability to produce high-quality welds and are commonly used in applications where aesthetics and precision are crucial.

Flux-Cored Welding Gun

Flux-cored welding guns are designed for flux-cored arc welding (FCAW) processes. These guns have a tubular wire filled with flux, which provides a shielding gas to protect the weld pool from atmospheric contamination. Flux-cored welding guns are preferred in applications that require high deposition rates and where welding conditions may be less ideal, such as outdoor or windy environments.

Uses of Welding Guns

MIG welding

MIG welding guns are primarily used for MIG welding processes. This includes applications such as automotive repair, fabrication, and construction, where high deposition rates and ease of use are essential. MIG welding guns are versatile and can be used on various metals, including steel, stainless steel, and aluminum.

TIG welding

TIG welding guns are commonly used in TIG welding processes, which demand precise control and high-quality welds. They are often favored for applications that require exceptional weld aesthetics, such as artwork, jewelry, or specialized machinery. TIG welding guns can be used on a wide range of materials, including stainless steel, aluminum, and copper.

Flux-cored welding

Flux-cored welding guns are primarily used for flux-cored arc welding processes. They excel in applications that require high deposition rates, such as heavy fabrication, shipbuilding, or structural steel projects. Flux-cored welding guns can handle various materials, including mild steel, stainless steel, and some alloys.

This image is property of qph.cf2.quoracdn.net.

Comparison between Welding Torch and Welding Gun

Fuel source

One key difference between welding torches and welding guns is the fuel source they utilize. Welding torches rely on fuel gases, such as acetylene or propane, which are burned to produce a flame for welding. On the other hand, welding guns use electricity as their power source to create an arc between the electrode and workpiece.

Operation

Welding torches and welding guns also differ in their operation. A welding torch requires a constant supply of fuel gas and oxygen, which are controlled by valves, to create the flame. The welder manually ignites the flame and adjusts its intensity using the torch’s controls. In contrast, a welding gun relies on an electrical current supplied by a welding machine. The welder activates the arc by pressing the trigger, and the current flows through the electrode, creating the necessary heat for welding.

Techniques used

Due to the differences in operation, welding torches and welding guns employ different techniques. Welding torches utilize a flame-based process, allowing for various welding techniques such as oxy-fuel welding, cutting, brazing, and heating. Welding guns, on the other hand, utilize an arc-based process, enabling techniques such as MIG welding, TIG welding, and flux-cored welding.

Suitability for different welding processes

Welding torches are generally well-suited for processes that require a high-temperature flame, such as cutting thicker metals or brazing. They are versatile and can be used in various applications. Welding guns, on the other hand, are designed for specific welding processes, such as MIG welding, TIG welding, or flux-cored welding. Each type of welding gun is optimized for its respective process and may not be as versatile as a welding torch.

Portability

In terms of portability, welding torches and welding guns differ as well. Welding torches are typically lightweight and portable, allowing for ease of movement and flexibility in different work environments. Welding guns, particularly those used for MIG welding or TIG welding, are often more cumbersome due to the additional components required, such as the power supply and wire feeder.

Versatility

Welding torches are generally more versatile than welding guns in terms of the applications they can handle. They can be used for cutting, joining, heating, and brazing various metals. Welding guns, on the other hand, are designed for specific processes and may have limitations in terms of the materials they can weld or the techniques they can employ.

Control

Both welding torches and welding guns provide a certain level of control, but in slightly different ways. Welding torches allow for precise control over the flame intensity, direction, and shape, which is crucial for achieving desired welding or cutting results. Welding guns, on the other hand, provide control over the electrical parameters, such as current, voltage, and wire feed speed, which influence the welding arc’s characteristics.

Applicability to different materials

Welding torches are capable of working with various materials, including steel, aluminum, copper, and some alloys. Depending on the specific torch and fuel gas used, certain materials may require additional flux or filler metal for successful welding. Welding guns, especially MIG welding guns, are versatile and can handle a wide range of materials, including steel, stainless steel, aluminum, and alloys, without the need for additional flux.

Cost

The cost of welding torches and welding guns can vary depending on factors such as brand, quality, and specific features. Generally, welding torches tend to be more affordable upfront, as they typically require a lower initial investment. However, the ongoing cost of fuel gases for torches should be taken into consideration. Welding guns, especially those used for more advanced processes like TIG welding, may have a higher upfront cost due to the need for a welding machine and associated accessories.

Safety considerations

Both welding torches and welding guns require proper safety precautions during operation. Welding torches utilize fuel gases, which can be flammable and require careful handling, storage, and ventilation. Welding guns, on the other hand, involve the use of electricity and welding arcs, which can pose electrical and fire hazards if not used correctly. Proper protective equipment, such as welding helmets, gloves, and clothing, should always be worn when using either tool.

Conclusion

In conclusion, welding torches and welding guns are distinct tools with different functionalities, applications, and operating mechanisms. Welding torches are primarily used for flame-based processes, offering versatility in cutting, joining, heating, and brazing metals. Welding guns, on the other hand, rely on electrical arcs and are designed for specific welding processes such as MIG welding, TIG welding, or flux-cored welding.

When choosing between a welding torch and a welding gun, it is crucial to consider the specific welding needs, materials, and techniques required for the task at hand. Factors such as the fuel source, operation, techniques used, portability, versatility, control, applicability, cost, and safety considerations should all be taken into account. By understanding the key differences between these tools, welders can make informed decisions and select the right tool to achieve optimal welding results.