In the ever-evolving world of technology and innovation, it’s hard to keep up with the latest trends. Just when you thought you knew everything there was to know about welding tools, along comes a new question: “Are there any eco-friendly welding tools available?” As we strive to become more environmentally conscious, it’s essential to explore the possibility of reducing the carbon footprint of industries such as welding. In this article, we will take a closer look at the current state of eco-friendly welding tools and evaluate their potential impact on our planet. So, let’s dive into the world of eco-friendly welding and discover if the future of this industry can be greener than ever before.

Review contents

Overview of Welding Tools

Definition of welding

Welding is a joining process that utilizes heat to fuse two or more pieces of metal together, creating a strong, permanent bond. This is achieved by melting the base metals and adding a filler material, which then solidifies to form a weld.

Types of welding

There are various types of welding techniques that are used depending on the specific project requirements. These include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, stick welding, and flux-cored arc welding, among others. Each method has its own unique characteristics and advantages, allowing for versatility in different applications.

Importance of welding tools

Welding tools play a crucial role in ensuring the success and efficiency of welding processes. These tools include welding machines, electrodes, filler metals, shielding gases, and safety equipment. Without the right tools, achieving high-quality welds would be difficult, if not impossible. Welding tools not only provide the necessary heat and protection but also contribute to the overall integrity and durability of the weld.

Environmental Impact of Traditional Welding Tools

Air pollution

Traditional welding processes often result in the release of harmful fumes and particulate matter into the air. These emissions, such as nitrogen oxides and volatile organic compounds (VOCs), contribute to air pollution and can have detrimental effects on human health and the environment. In densely populated areas or enclosed spaces, the concentration of pollutants can be even higher, posing a greater risk.

Toxic fumes

Many welding processes involve the use of electrodes or consumables that contain toxic substances, such as lead, chromium, and manganese. When these materials are melted during welding, toxic fumes are released into the air. Exposure to these fumes can lead to serious health problems, including respiratory issues, neurological disorders, and even cancer. The long-term effects on both welders and the surrounding environment can be significant.

Energy consumption

Traditional welding methods often require a substantial amount of energy to generate the necessary heat. This can contribute to increased energy consumption and carbon emissions, further exacerbating the environmental impact. Moreover, the use of outdated equipment and inefficient welding techniques can result in unnecessary energy wastage, adding to the overall carbon footprint of the welding process.

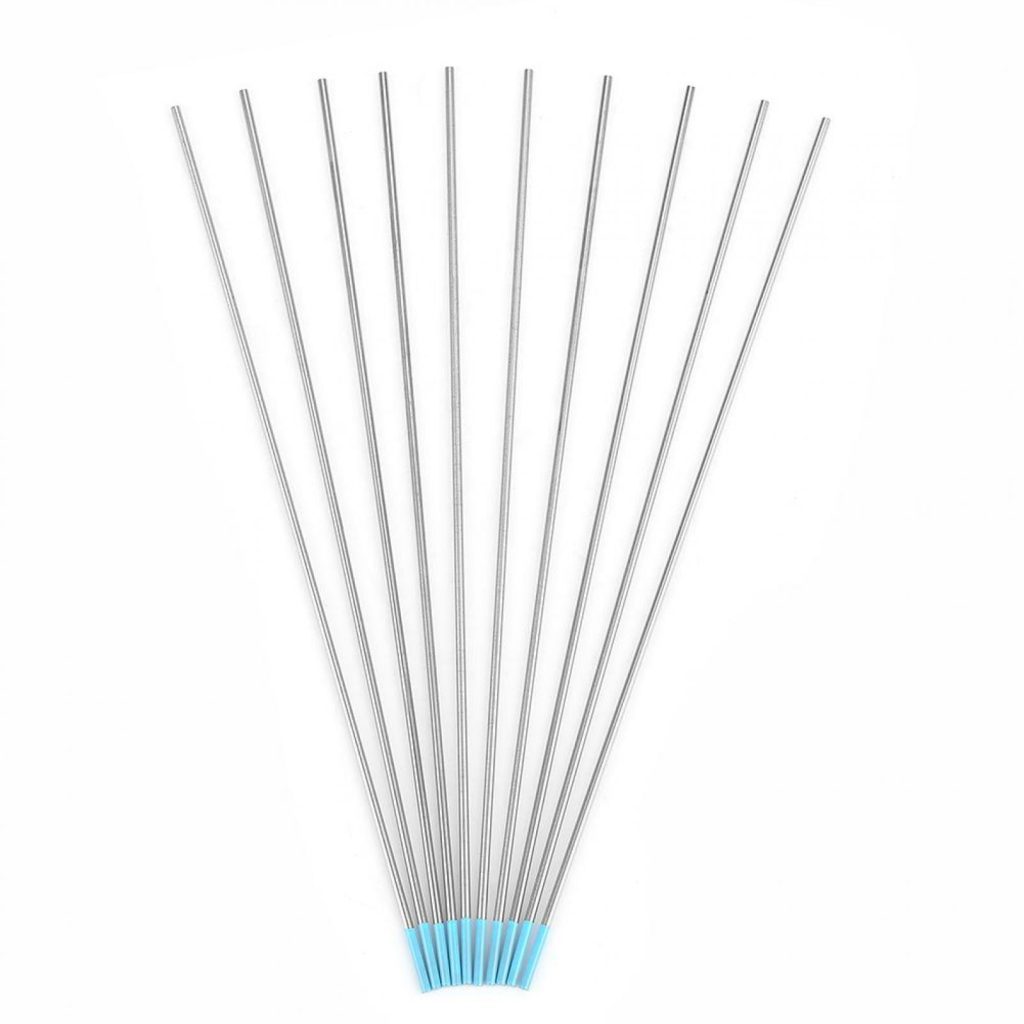

This image is property of Amazon.com.

Eco-friendly Welding Alternatives

Exploring eco-friendly welding options

In recent years, there has been a growing emphasis on developing eco-friendly alternatives to traditional welding methods. These alternatives aim to minimize the environmental impact of welding while still achieving high-quality welds. By exploring these options, welders can contribute to a more sustainable and greener future.

Introduction to eco-friendly welding tools

Eco-friendly welding tools encompass a range of innovative technologies and techniques that prioritize environmental sustainability. These tools focus on reducing air pollution, minimizing the release of toxic fumes, and optimizing energy efficiency. With advancements in eco-friendly welding, welders now have access to tools that can help mitigate the negative environmental impacts associated with traditional welding processes.

Eco-friendly Welding Processes and Techniques

Laser welding

Laser welding is a highly precise and efficient method that utilizes a concentrated beam of light to melt and join metal pieces together. This process eliminates the need for consumables and minimizes the release of toxic fumes. Furthermore, laser welding can achieve high-quality welds with minimal distortion, resulting in reduced material waste and increased efficiency.

Electron beam welding

Electron beam welding utilizes a high-velocity beam of electrons to melt and join metal components. This process is notable for its ability to create deep, narrow welds without the need for additional filler materials. As a result, electron beam welding reduces the release of hazardous fumes and minimizes the consumption of resources. It is commonly used in industries such as aerospace and automotive manufacturing.

Friction stir welding

Friction stir welding is a solid-state joining process that creates a bond between metal pieces through frictional heating and mechanical pressure. Unlike traditional welding techniques, friction stir welding does not involve melting the base metals, thereby eliminating the release of toxic fumes. This method is renowned for its ability to produce high-strength, defect-free welds, making it suitable for a wide range of applications.

This image is property of eurekaoxygencompany.com.

Advantages of Using Eco-friendly Welding Tools

Reduction in carbon emissions

One of the significant advantages of eco-friendly welding tools is the reduction in carbon emissions. By utilizing more energy-efficient processes and technologies, eco-friendly welding reduces the overall energy consumption and carbon footprint. This is particularly crucial in industries where welding is a primary operation, such as automotive manufacturing and construction, as it contributes to the overall sustainability of the sector.

Minimized release of hazardous materials

Eco-friendly welding tools prioritize the safety of both the welders and the environment by minimizing the release of hazardous materials. By utilizing processes that do not involve the melting of toxic filler materials or electrodes, the potential exposure to harmful fumes is significantly reduced. This ensures a healthier work environment and reduces the long-term environmental impact associated with traditional welding methods.

Increased energy efficiency

Eco-friendly welding tools are designed to optimize energy efficiency and minimize energy wastage. Advanced technologies, such as laser welding and electron beam welding, require lower energy inputs compared to traditional methods. By reducing the energy consumption of the welding process, eco-friendly tools not only contribute to a greener environment but also lead to cost savings for welders and businesses in the long run.

Innovations in Eco-friendly Welding Technology

Developments in electrode coatings

Researchers and manufacturers are constantly exploring new ways to develop electrode coatings that are more environmentally friendly. By replacing or reducing the toxic substances present in electrode coatings, the release of harmful fumes during welding can be significantly reduced. These innovations aim to provide welders with safer alternatives that maintain high welding performance while minimizing the environmental impact.

Improvements in shielding gases

Shielding gases are crucial in protecting the weld pool from atmospheric contamination and ensuring the quality of the weld. Innovations in eco-friendly welding technology focus on developing shielding gases that have minimal environmental impact. By substituting traditional gases with more sustainable options, such as argon-helium mixtures, the release of greenhouse gases can be reduced, contributing to a greener welding process.

Advancements in welding equipment

Manufacturers are continually improving welding equipment to make it more energy-efficient and eco-friendly. For example, advancements in power sources and controls allow for better regulation of energy input during the welding process, resulting in reduced energy consumption and emissions. Additionally, the integration of advanced sensors and automation technology improves the accuracy and efficiency of welding, minimizing material waste and further enhancing the sustainability of the welding process.

This image is property of Amazon.com.

Applications and Industries Utilizing Eco-friendly Welding

Automotive industry

The automotive industry is one of the sectors at the forefront of adopting eco-friendly welding tools and techniques. With the increasing demand for electric vehicles and stringent environmental regulations, automakers are investing in sustainable manufacturing processes, including welding. Eco-friendly welding methods, such as laser welding and friction stir welding, are being employed to create lightweight and durable vehicle structures, reducing both fuel consumption and carbon emissions.

Aerospace industry

The aerospace industry requires highly precise and reliable welding techniques to maintain the structural integrity and safety of aircraft components. Eco-friendly welding processes, such as electron beam welding and laser welding, are extensively used in aerospace manufacturing. These methods ensure the production of high-quality welds while minimizing the release of toxic fumes and reducing material waste. By adopting eco-friendly welding, the aerospace industry can enhance its environmental sustainability and meet stringent industry standards.

Construction sector

The construction sector is another significant industry that benefits from eco-friendly welding tools and practices. Sustainable construction practices prioritize energy efficiency and environmental conservation. By utilizing eco-friendly welding techniques, such as friction stir welding and laser welding, construction companies can reduce on-site emissions, minimize material waste, and construct more durable structures. These eco-friendly welding methods also contribute to the overall energy efficiency of buildings, making them more environmentally friendly.

Training and Certification for Eco-friendly Welding

Importance of proper training

Proper training is essential for welders to effectively and safely utilize eco-friendly welding tools and techniques. As eco-friendly welding methods differ from traditional methods, it is crucial for welders to receive specialized training to understand the nuances and best practices associated with these technologies. Training programs provide welders with the necessary knowledge and skills to utilize eco-friendly welding tools, ensuring the success and efficiency of the welding process while minimizing the environmental impact.

Certifications and programs available

There are various certifications and programs available that focus specifically on eco-friendly welding. These certifications, such as the Certified Eco-Welder program, provide welders with recognition for their proficiency in utilizing sustainable welding practices. Additionally, many vocational schools and training institutions offer specialized programs in eco-friendly welding, equipping welders with the skills needed to excel in an environmentally conscious industry. By obtaining these certifications and attending programs, welders can enhance their career prospects while contributing to a greener welding industry.

This image is property of Amazon.com.

Cost Considerations For Eco-friendly Welding Tools

Initial investment

The initial investment required for eco-friendly welding tools may be higher compared to traditional welding equipment. Advanced technologies, such as laser welding machines and electron beam welders, often come with a higher upfront cost. However, it is important to consider the long-term benefits and cost savings associated with eco-friendly welding. Reduced energy consumption, lower material waste, and the potential for increased efficiency can offset the initial investment over time.

Long-term savings

Although the initial investment may be higher, utilizing eco-friendly welding tools can lead to significant long-term savings. The reduction in energy consumption translates to lower electricity bills, offering cost savings in the operation of welding equipment. Additionally, by minimizing material waste and optimizing weld quality, eco-friendly welding tools contribute to improved productivity and reduced rework, further reducing costs. These long-term savings make eco-friendly welding a financially viable choice for welders and businesses.

Challenges in Adopting Eco-friendly Welding Tools

Resistance from traditional welders

One of the challenges in adopting eco-friendly welding tools is the resistance from traditional welders who are accustomed to using conventional techniques. The transition to eco-friendly welding may require relearning and adapting to new processes and equipment. However, by providing proper training and highlighting the advantages of eco-friendly welding, it is possible to overcome this resistance and promote the adoption of sustainable practices.

Availability and accessibility

Another challenge lies in the availability and accessibility of eco-friendly welding tools and technologies. Initially, eco-friendly welding tools may be less readily available compared to traditional equipment due to their relatively recent development. However, as demand increases and manufacturers focus on scaling up production, the availability and accessibility of eco-friendly welding tools are expected to improve.

Lack of awareness

A lack of awareness about eco-friendly welding options can also pose a challenge to their adoption. Many welders and businesses may not be familiar with the advancements in eco-friendly welding technology or the potential benefits it offers. Raising awareness through training programs, industry conferences, and educational campaigns can help bridge this knowledge gap and encourage the wider adoption of eco-friendly welding tools and processes.

In conclusion, eco-friendly welding tools offer a promising solution to mitigate the environmental impact of traditional welding processes. Through the development of innovative technologies and techniques, such as laser welding, electron beam welding, and friction stir welding, welders now have access to more sustainable alternatives. These tools not only reduce air pollution and minimize the release of toxic fumes but also contribute to increased energy efficiency. Industries such as automotive, aerospace, and construction are already embracing eco-friendly welding, recognizing the long-term benefits for both the environment and their bottom line. However, challenges such as resistance from traditional welders, availability, and lack of awareness must be addressed to facilitate the widespread adoption of eco-friendly welding tools. With proper training, certifications, and a focus on long-term cost savings, eco-friendly welding can become the new standard, ensuring a greener and more sustainable future for the welding industry.

This image is property of i5.walmartimages.com.