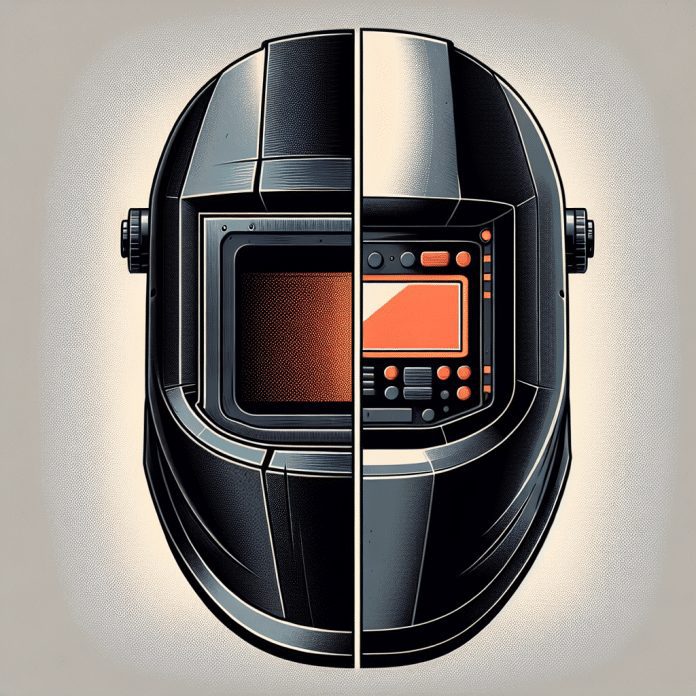

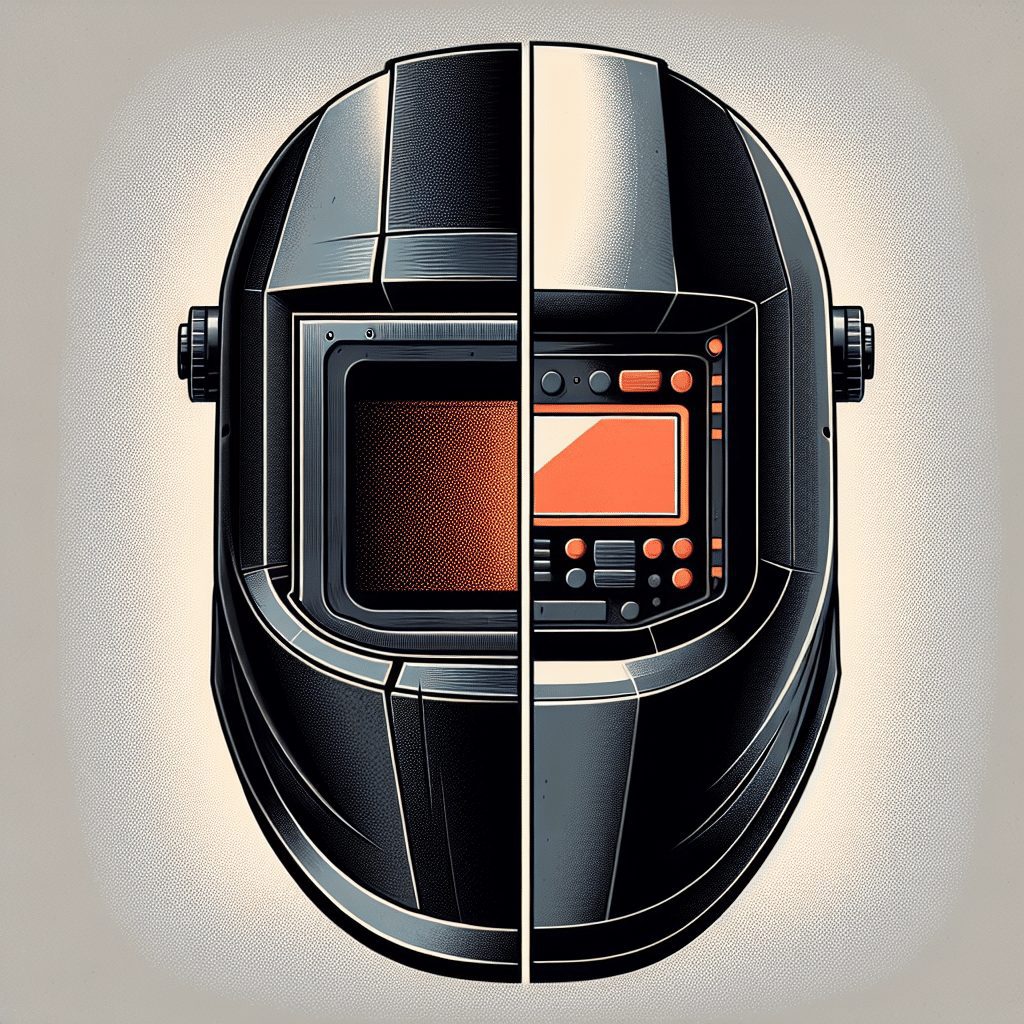

In the world of welding, there are two main types of helmets: passive and auto-darkening. Each has its own set of benefits and drawbacks, and choosing the right one can greatly impact your welding experience. Passive helmets are the traditional option, with a fixed shade lens that stays dark throughout the welding process. On the other hand, auto-darkening helmets use advanced technology to automatically adjust the shade level depending on the intensity of the arc. This article will compare the pros and cons of both types of helmets, helping you make an informed decision for your future welding endeavors.

Review contents

Passive Welding Helmets

Design

Passive welding helmets are designed with simplicity in mind. They typically feature a fixed shade lens that provides a constant level of protection. These helmets have a classic, traditional look and are often preferred by experienced welders who appreciate their straightforward design.

Functionality

The functionality of passive welding helmets is quite basic. They rely on a standard lens that does not automatically darken. This means that the lens is always at the same shade, typically between shades 9 and 13, depending on the model. To begin welding, you have to manually lower the helmet, which activates the lens and protects your eyes from the bright welding arc.

Cost

One of the significant advantages of passive welding helmets is their affordability. Compared to their auto-darkening counterparts, passive helmets are generally cheaper. This makes them an excellent choice for welders who may be on a tight budget or only engage in welding occasionally.

Auto-Darkening Welding Helmets

Design

Auto-darkening welding helmets incorporate advanced technology to provide a more convenient and user-friendly experience. These helmets feature a liquid crystal display (LCD) lens that automatically darkens when the welding arc is initiated. The design is sleek and modern, often with additional features such as adjustable headgear for a secure and comfortable fit.

Functionality

The primary functionality of auto-darkening welding helmets lies in their ability to automatically adjust the lens shading based on the intensity of the light emitted by the welding arc. This eliminates the need to manually raise or lower the helmet, allowing for a smoother and uninterrupted workflow. The lens quickly darkens to the required shade, usually within milliseconds, ensuring optimal eye protection.

Cost

Auto-darkening welding helmets typically come with a higher price tag compared to passive helmets. The advanced technology and electronic components involved contribute to the increased cost. However, it’s essential to consider the long-term benefits and improved convenience that auto-darkening helmets provide, which may outweigh the initial investment for many welders.

Pros of Passive Welding Helmets

Affordability

One of the most significant advantages of passive welding helmets is their affordability. Since they don’t require any advanced technology or electronic components, passive helmets are generally more economical than their auto-darkening counterparts. This makes them a practical choice, especially for beginner welders or those on a budget.

Durability

Passive welding helmets are known for their durability. They are typically built to withstand the rigors of a welding environment, including heat, sparks, and impact. With fewer moving parts and simpler construction, these helmets tend to have a longer lifespan compared to more complex auto-darkening helmets.

Suitable for certain welding applications

Passive welding helmets are particularly suitable for specific welding applications. For example, if you primarily engage in heavy-duty welding projects that entail consistent and prolonged exposure to the intense welding arc, a passive helmet may be a better choice. Its fixed shade lens offers continuous protection without the need for constant adjustment.

Cons of Passive Welding Helmets

Limited visibility

One of the downsides of passive welding helmets is their limited visibility. The fixed shade lens means that the view remains the same, regardless of the lighting conditions. This can make it challenging to see details or work on projects that require precise vision. Welders may need to lift the helmet frequently to assess their work, which can be time-consuming and disrupt the workflow.

Need to manually adjust the lens

Unlike auto-darkening helmets, passive helmets require manual adjustment of the lens. Before you can start welding, you need to lower the helmet, which activates the lens and darkens the view. This manual process can be repetitive, especially when engaging in various welding tasks, leading to potential frustration and added strain on the neck and shoulders.

May cause eye fatigue

Constant exposure to the bright welding arc without the ability to auto-adjust the lens may lead to eye fatigue in some welders. The fixed shade lens can strain the eyes, particularly during long welding sessions. However, this can be mitigated by taking regular breaks and ensuring proper eye protection to reduce the risk of fatigue and eye strain.

Pros of Auto-Darkening Welding Helmets

Automatic lens adjustment

The automatic lens adjustment in auto-darkening welding helmets is a game-changer. These helmets use advanced technology to detect the brightness of the welding arc and instantly darken the lens to the appropriate shade. This feature ensures maximum eye protection without the need for manual adjustments, allowing for a seamless and uninterrupted welding experience.

Better visibility

Auto-darkening welding helmets offer superior visibility compared to their passive counterparts. With an adjustable shade lens, welders can see their work clearly, regardless of the surrounding lighting conditions. This enhanced visibility enables precise and accurate welding, making auto-darkening helmets the preferred choice for intricate projects that require attention to detail.

Reduced eye fatigue

The ability of auto-darkening welding helmets to automatically adjust the lens shading significantly reduces eye fatigue. Welders no longer need to strain their eyes by constantly adapting to the changing lighting conditions. The continuous eye protection provided by the helmet contributes to reduced eye strain, making long welding sessions more comfortable and less tiring.

Cons of Auto-Darkening Welding Helmets

Higher cost

One of the notable downsides of auto-darkening welding helmets is their higher cost. The advanced technology and electronic components involved in the automatic lens adjustment contribute to the increased price. However, it’s essential to consider the improved functionality and long-term benefits that justify the investment for professional welders or those who frequently engage in welding work.

Complex design

Auto-darkening welding helmets are more complex in design compared to their passive counterparts. The incorporation of electronic components and adjustable features can make these helmets bulkier and heavier. Additionally, the user-friendly features may require some initial familiarization to ensure optimal usage. However, once you become accustomed to the design, the added functionalities can greatly enhance the welding experience.

Battery dependency

Auto-darkening welding helmets rely on batteries to power the auto-adjustment feature. This dependence on batteries introduces an additional element of maintenance and potential inconvenience. It is crucial to ensure that the batteries are charged or replaced when necessary to avoid interruptions during welding tasks. However, with proper battery management, this potential con can be minimized.

Factors to Consider When Choosing a Welding Helmet

Welding applications

Consider the types of welding applications you will be involved in regularly. Different welding techniques and materials may require specific helmet characteristics. Evaluate whether a passive or auto-darkening helmet is better suited for your specific welding needs.

Budget

Determine your budget before making a purchase decision. Passive welding helmets are generally more affordable compared to auto-darkening helmets. However, keep in mind the long-term benefits and convenience that an auto-darkening helmet offers, which may outweigh the initial cost.

Comfort and fit

A welding helmet should provide a secure and comfortable fit to ensure optimal protection and minimize distractions while working. Consider adjustable headgear, ergonomic design, and weight distribution to choose a helmet that suits your comfort preferences.

Lens reaction time

For auto-darkening helmets, lens reaction time is an essential factor to consider. A quicker lens reaction time ensures minimal delay in darkening the lens when exposed to the welding arc. Look for helmets with fast-switching technology for optimal eye protection.

Quality and durability

Evaluate the quality and durability of the welding helmet before purchasing. Look for helmets made with robust materials that can withstand the harsh welding environment, including heat, sparks, and impact. Check customer reviews and choose from reputable brands known for their reliability.

Conclusion

When choosing between passive and auto-darkening welding helmets, it’s essential to consider your specific needs, preferences, and budget. Passive helmets offer affordability and durability, but may lack convenience and visibility. Auto-darkening helmets provide automatic lens adjustment, improved visibility, and reduced eye fatigue, but come at a higher cost and may have a more complex design. Remember to assess factors such as welding applications, budget, comfort, lens reaction time, and quality to make an informed decision. Ultimately, the right welding helmet will provide the necessary protection and comfort for a safe and enjoyable welding experience.